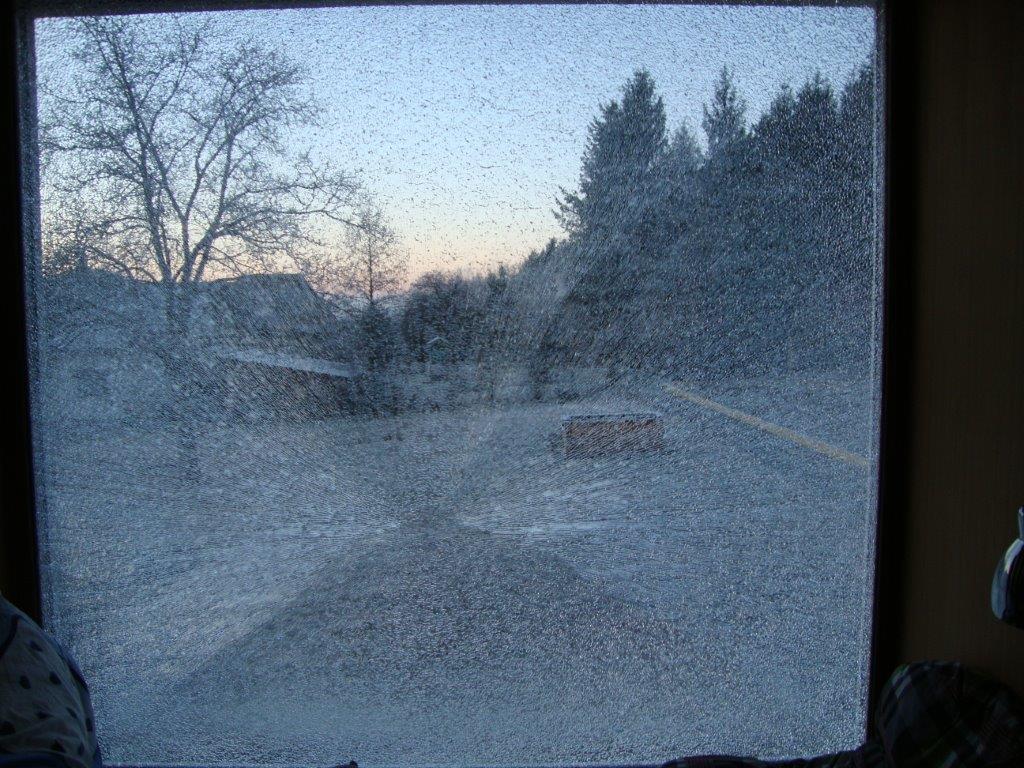

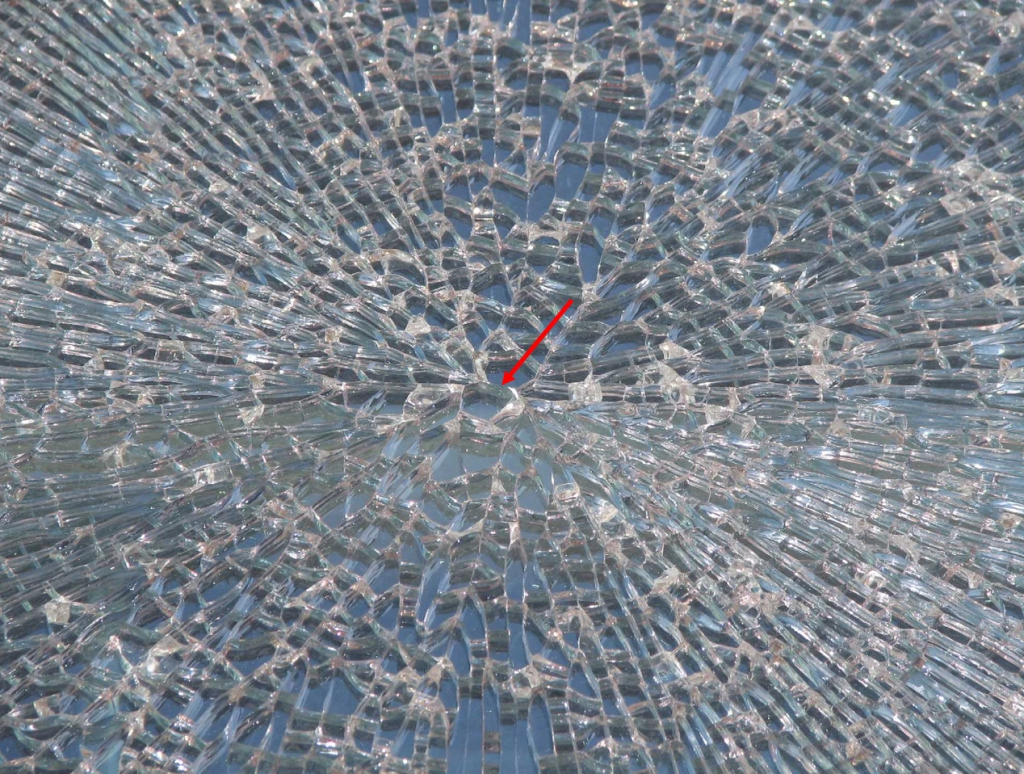

The basic raw materials of the window glass are silicon dioxide or quartz (SiO2 – 72%), sodium oxide (Na2O – 14 %), calcium oxide (CaO – 10 %), magnesium oxide (MgO – 3 %) and aluminium oxide (Al2O3 – 1 %). During the process of melting of glass components, small nickel sulphide (NiS) crystals can occur, which present impurities in the mixture. During the tempering process at temperatures up to 620 °C, the volume of these impurities increases. The next step is the rapid cooling or quenching of the glass. As in such a short time, NiS can not revert to the initial volume state, it becomes “frozen” in its current form which causes additional local tensions in tempered glass. The situation is similar to delay-action bomb, which can be triggered at any time when exposed to sun rays. This causes the heating of glass and consequently the increase of the volume of NiS, resulting in additional internal stresses. When these tensions exceed the acceptable level, a spontaneous fracture of glass occurs and has a characteristic mesh shape. It originates from one point around which the local fracture in the form of a butterfly is present and continues further into the net over the entire glass.

Spontaneous fracture due to inclusion of NiS is very rare and can be avoided with the previous heat soak test (HST) where the tempered glass is heated up to 290 °C for a certain period of time. In this case, 99 % of tempered glass with NiS inclusions and are therefore subject to the risk of spontaneous fracture is eliminated.