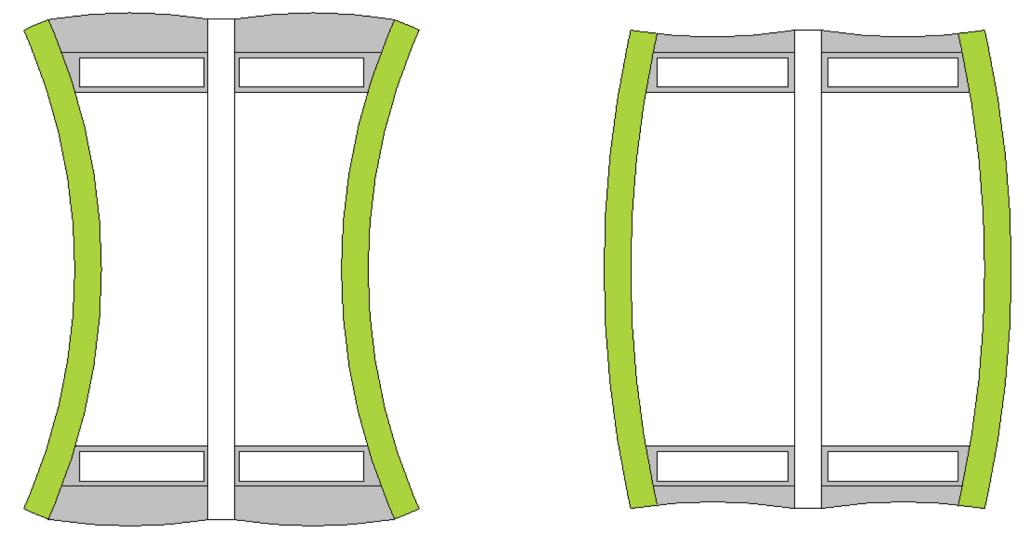

Double and triple glazings are build of float glass and gas chambers in between. Due to the physical laws for gas, the gases in the chambers expend or contract and with this influence on the deflection of float glass. The outside glass becomes concaved or convexed. This effect deforms the view through glass or it can also be seen as an enlarged or minimized objects that reflecets from the glass surface. In triple glazing, the two gas chambers act as one. Middle float glass does not deform due to its neutral position, but the pressure on the outside glass is huge. Large deformations can lead to glass breakage and in extreme situations to delamination of the adhesives near the spacers (at the glass edges) and consequently to condensation in the gas chamber.

Figure 1: Concaved and convexed glass, due to the expansion or contraction of gasses in the gas chamber

The effect of temperature and pressure changes on the expansion or contraction of gas in the chambers should not be neglected when glass is build in houses that lie 300 m above the location of the glass production (usually all houses that are 600 m above the sea level). The load on the glass only due to sea level difference in such cases, is 7,2 kPa. To eliminate this load we use glazings produced with altimeters. This is a special process with which preloaded pressure or suction is applied in the gas chamber. If produced correctly the outside and inside pressure even when the glass is installed and there is no additional pressure on the glass surfaces afterwards. Prior to altimeters, gas valves were often used to even the pressure at the location of the house. These are nowadays rarely used since they do not allow to even the pressure when glazings are glued-in the window frame.

Temperature (T) differences present an additional load on the glass. If the T difference between day and night is 20 °C, this means additional pressure on the glass in load of 8,5 kPa. We can not avoid the temperature load and can prevent the glass from breakage only with using thicker or tempered glass – in both cases glasses with higher strength. The influence of pressure on glass and its edge is bigger if glazings are small. Therefore, on the disbelieve of many, the need for stronger and more resistant glass, is bigger in the case of small windows.

Figure 2: high altitude object in France – visokogorje

SOURCE:http://www.reflex.si/si/files/default/knjiga-gradimo-s-steklom/Gradimo_s_steklom_Book_SLO_web.pdf