Typical problem areas of interest include structural analysis, heat transfer, fluid flow, which all play a major role during the development of the windows.

Complex physical problems are simulated with approximate numerical models. Each model is divided into smaller simple sections (elements) of finite dimensions with defined mechanical properties. The finite element method formulation of the problem results in a system of equations. The simple equations that model these finite elements are then assembled back into a larger system of linear equations or so-called stiffness matrix, that must be solved in order to obtain an approximate solution to the differential equation.

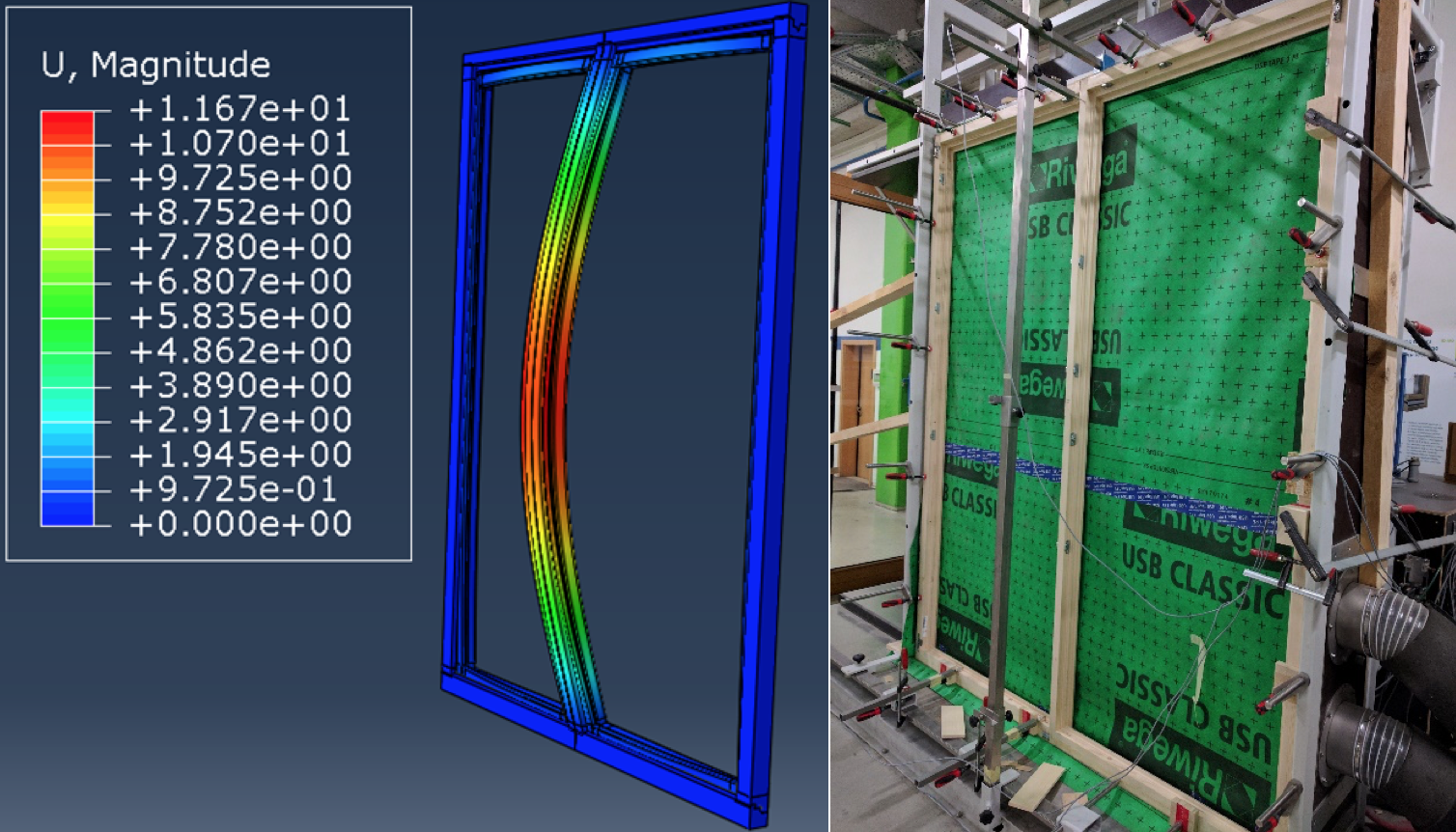

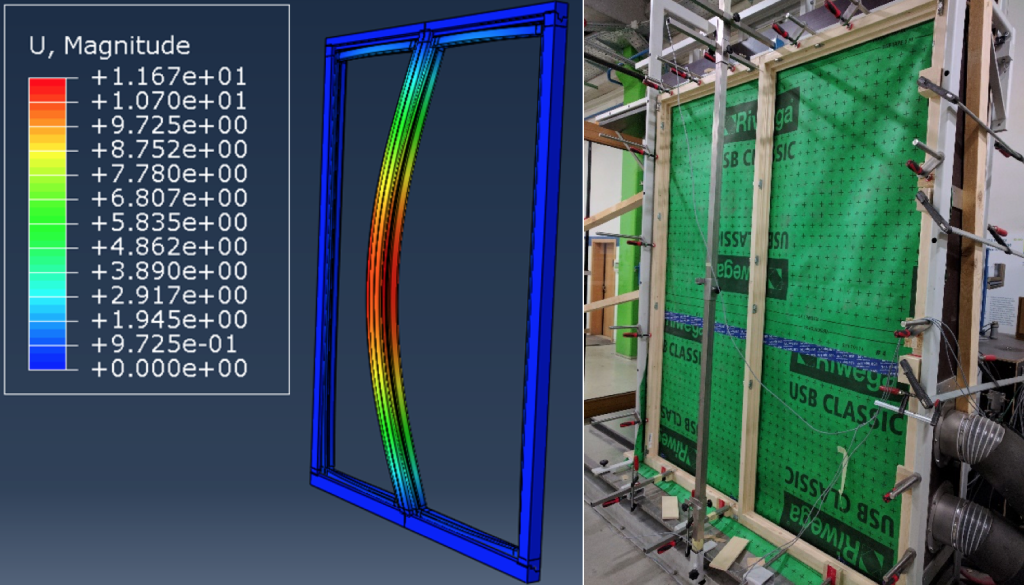

Comparison between the FEM (left) and physical model (right) of wooden window (legend shows the displacement in mm at certain load)

In the recent years, FEM had found new applications within the different areas of industry, with the development of numerical software and computers. Use of the FEM on the development of the window structures is new and provides great opportunity to obtain insight in mutual contact between wooden elements of the frame, as well as frame and different materials, which would be otherwise impossible.

One of the most complex task represents definition of material parameters for biomaterials. Since the wood represents approximately 90 % of the high-quality window frame, this step requires a lot of physical testing to obtain adequate parameters within different directions of the wood (longitudinal and transversal).

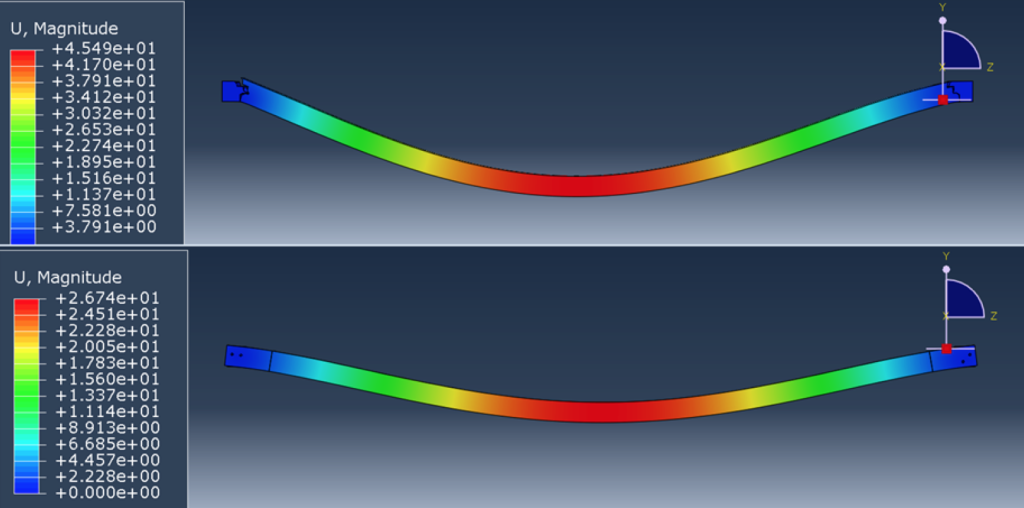

Comparison of FEM models with two different designs (legend shows the displacement in mm at certain load)

Application of the numerical simulations in the wooden window design provide opportunity to test: different contacts, different materials, individual elements or whole assemblies, thermal properties, simulate forces during transportation and manipulation during installation, etc.

With the use of FEM, it is possible to evaluate different solutions for individual client’s requests within early design stage, and thereby provide best possible solutions in the shortest amount of time. FEM is most widely used in car industry and structural engineering and is definitely the future opportunity for wooden windows, development and evaluation.